Our

Infrastructure

Steam Sterilization

The potential for pathogens to get into the food supply has resulted in the trend towards more stringent regulations. Sterilization is necessary for the complete destruction of all microorganisms.

We take pride in our steam sterilizer which is a key technological advancement, while maintaining high quality. Steam sterilization is a unique process to decontaminate spices using saturated steam.

Salient Features

Continuous decontamination of bacteria and pathogens – 5 log kills are typical.

Learn More Here

MBR Treatment

Methyl Bromide is most widely used fumigant for quarantine purposes. It is a preferred fumigant for most of the quarantine authorities around the world, because of its good penetrating ability, rapid action, high toxicity to a broad spectrum of insects and pests.

This odorless gas is quite stable and normal aeration at the end of fumigation and processing re4leases unreacted fumigant and brings down the residues to insignificant levels.

BRC Certified Unit

Our Spice Milling Division, SAMAY AGRO PVT.LTD., is a progressive modern unit that is BRC “A” certified by TUV. The BRC certificate is an assurance to our consumer that we meet all the safety, quality and operational criteria required within a food processing unit in order to satisfy the statutory obligations and those relating to the consumer protection.

Our Samay Agro Factory is completely dedicated to the processing of spices for the export market with a capacity of 3000MT.The design and construction confirms to the International Standard for food processing units. It facilitates separate stores for raw material, finished goods and packaging material and has in house quality assurance laboratory and all the other facilities to cater to the current standard of safety, quality and hygiene worldwide.

Laboratory

Samples from raw to finished products undergo quality checks.

Our lab has chemical, microbiology, and analytical divisions.

We analyze ash, fiber, moisture, aflatoxins, ochratoxins, and more.

Experienced team uses accepted methods to provide analysis certificates.

Cold Storage Facility

Cold storage facility plays vital role in maintaining quality and extending shelf life of produce as well as reduce transport bottlenecks and ensures seamless supply of raw materials for year round.

We at SuruchiGroup, possess our own Cold storage facility under the name of Suruchi Cold Storage Pvt. Limited.

Quality Procurement

We value 'Quality at Priority'. After 37 years, we believe only high-quality materials provide final products that meet customer needs. Suruchi group never compromises on raw material quality.

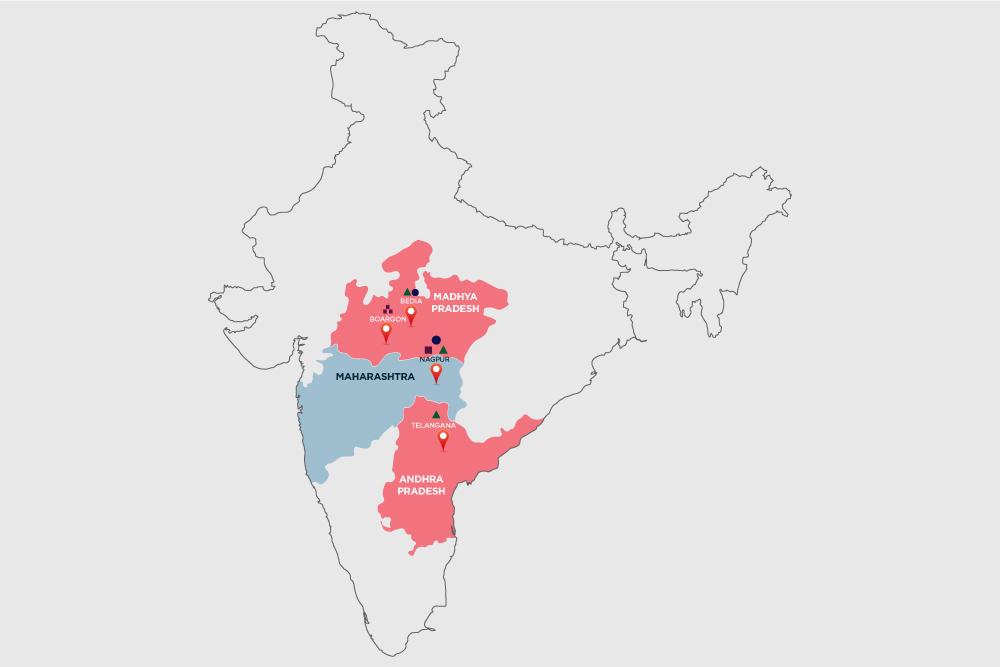

Suruchi has a Procurement Plan to ensure quality. We buy good quality chillies. Our Purchase Team uses their knowledge to maintain this quality when buying directly from farmers.

For other materials, we trust certified suppliers with a Certificate of Analysis.

We do Chemical, Microbiological, and Sensory tests in our lab before receiving raw materials. Approved materials meet all criteria and are stored in a controlled environment.

Stemless Processing Zone

We monitor strictly for foreign material and contaminants, ensuring high quality from the start.

Our facility gives us an edge to avoid allergens, a serious problem in many countries.